Pulse Vacuum Autoclave NPVA-110 is designed with an 800L capacity for optimal sterilization performance. It ensures a high sterilization rate of 99.97% with its advanced air filter system. Our unit includes an automatic drainage system to manage water based on temperature and pressure. It uses a durable stainless steel sanitary pipeline system with clamp connections. This pulse vacuum autoclave is controlled by an imported Siemens PLC and a color touchscreen for precision.

FAQ for Pulse Vacuum Autoclave NPVA-110

1: How safe is the sterilization process?

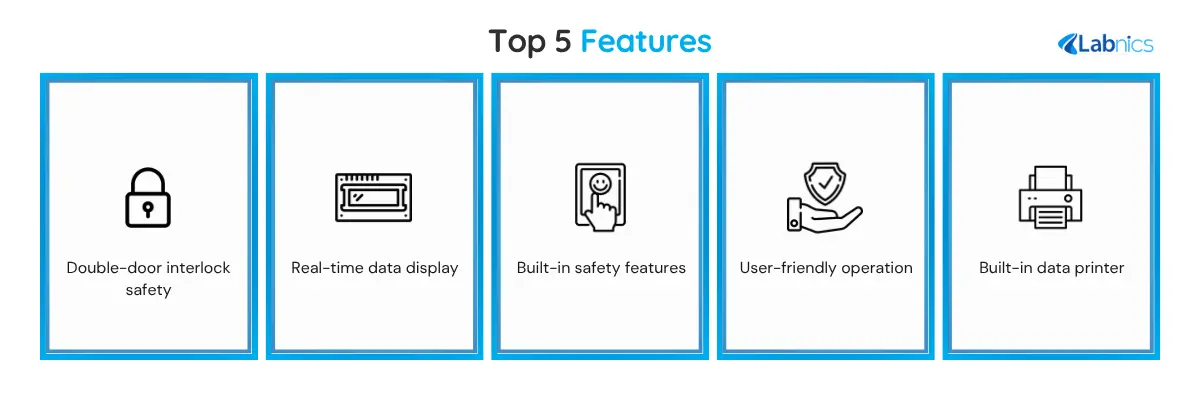

The Pulse Vacuum Autoclave includes double-door safety interlocks and pressure-temperature safety locks to prevent accidental openings. The sealing ring is automatically inflated for tight sealing, reducing leakage risk and enhancing safety during operation.

2: Is the Pulse Vacuum Autoclave NPVA-110 easy to operate?

The Pulse Vacuum Autoclave is equipped with a Siemens PLC control system and a color touch screen for intuitive, fully automated operation. Parameters like temperature, pressure, and time are displayed in real time for easy monitoring.

3: How is process data managed?

The Pulse Vacuum Autoclave includes a built-in micro-dot printer for real-time process printing and a paperless recorder for digital record-keeping. This helps maintain clear documentation for quality audits and traceability.

4: How durable is the sealing system?

The sealing ring is made from high-quality, high-tear-resistant silicone rubber with a special surface coating. It can withstand up to 1500 sterilization cycles, offering long-term durability.

5: Does the Pulse Vacuum Autoclave NPVA-110 support energy and water efficiency?

Yes, an optional water-saving and noise-reduction system reduces water use by up to 30% and lowers vacuum pump noise. This helps improve operational efficiency and reduce environmental impact.

6: How does the vacuum function improve sterilization performance?

The vacuum function removes trapped air from the chamber and instruments, allowing steam to reach all surfaces effectively. This ensures uniform sterilization, even for items with intricate designs or internal cavities.

7: Does the Pulse Vacuum Autoclave have safety features during operation?

The Pulse Vacuum Autoclave is equipped with automatic door locking and safety interlocks that prevent the chamber from being opened mid-cycle. These features help maintain safe operation and prevent steam-related accidents.

8: What material is used for the chamber construction?

The chamber is made of high-grade, corrosion-resistant stainless steel that offers durability and easy cleaning. It helps maintain hygiene and withstands high-temperature steam over repeated use.

9: How often should the Pulse Vacuum Autoclave be maintained?

Regular maintenance should be done monthly for basic cleaning and quarterly for more detailed inspections. Preventive servicing helps maintain optimal performance and extends the machine’s lifespan.