Any Query ?

A-Z Lab Equipment

Laboratory Equipment

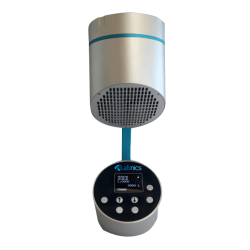

Water Testing

- BOD Meter

- COD Analyzer

- COD Digester

- Conductivity Controller Analyzer

- Conductivity Meter (Bench-top)

- Conductivity Meter (Portable)

- Dissolved Oxygen meter (Benchtop)

- Dissolved Oxygen Sensor

- Fluoride Analyzer (Portable)

- Multi-Parameter Meter (Benchtop)

- Multiparameter Water Quality Analyzer

- Mutliparameter Conductivity Meter (Portable)

- pH Conductivity Meter

- pH Controller Analyzer

- pH Meter (Benchtop)

- pH ORP Meter

- pH Tester

- TDS Meter

- Turbidity Meter

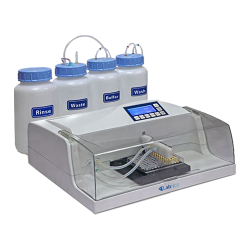

Suggested Products

Copyright ©2024 All rights reserved | Labnics.com