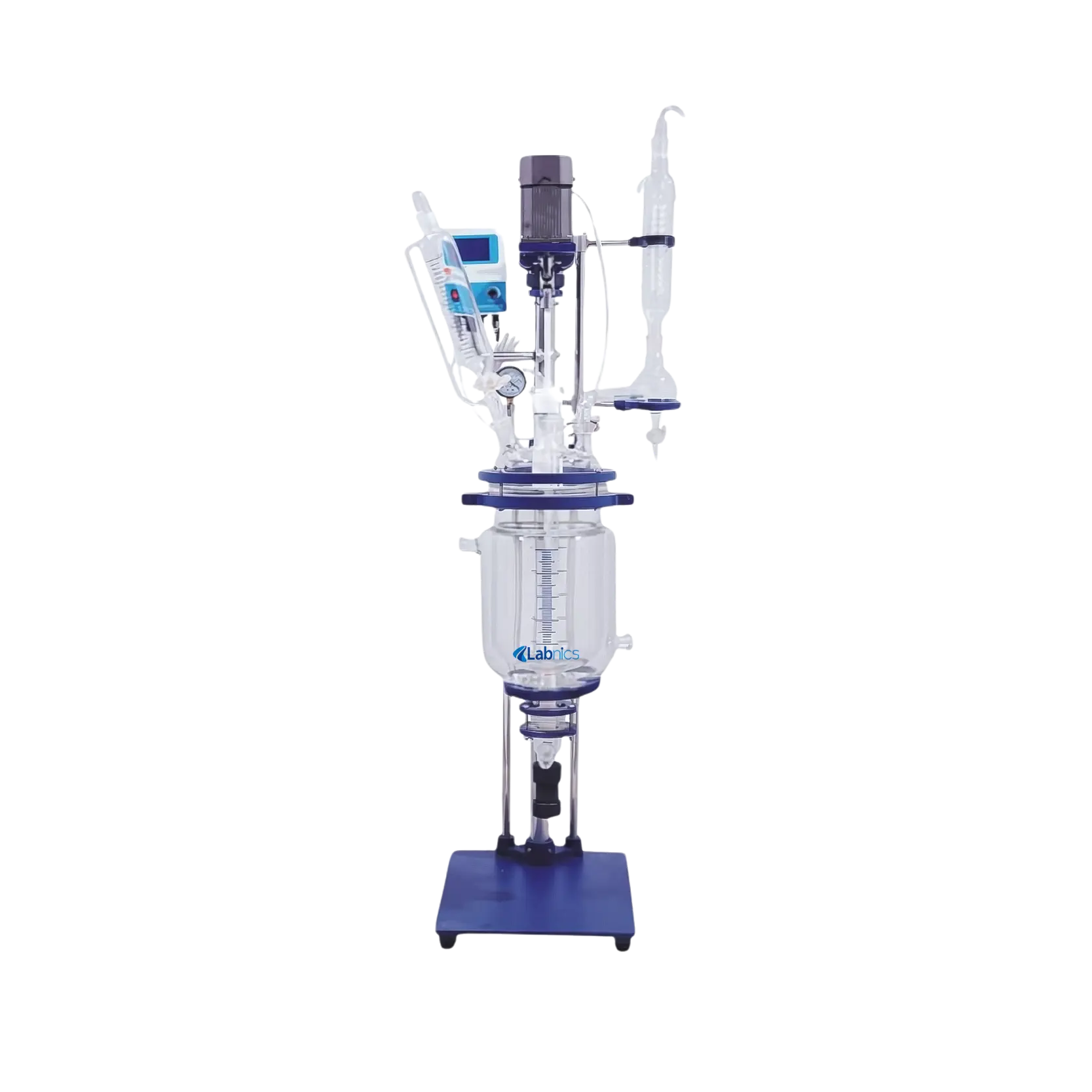

Jacketed Glass Reactor NJGR-200 features a 1-liter reaction vessel, making it suitable for small-scale applications. It has a 0.25-liter constant-pressure funnel allows precise reagent addition under controlled pressure. This unit can operate within a broad temperature range of -80°C to +300°C. It uses a 304 stainless steel frame that ensures strong mechanical support and resistance to corrosion. Our reactor includes a digital control panel for accurate adjustment of parameters.

FAQ for Jacketed Glass Reactor NJGR-200

1: Is the Jacketed Glass Reactor NJGR-200 safe for vacuum applications?

The Jacketed Glass Reactor is compatible with vacuum operation up to -0.098MPa, enhancing reaction efficiency and safety. This is especially useful for processes that require reduced pressure conditions.

2: Does the Jacketed Glass Reactor NJGR-200 have good sealing and mixing?

Yes, our Jacketed Glass Reactor features PTFE sealing and a stirring system with ceramic bearings and mechanical seals. This design ensures minimal leakage, high-temperature tolerance, and smooth mixing.

3: How is temperature controlled in the Jacketed Glass Reactor NJGR-200?

The jacketed design allows circulation of hot or cold fluid through the outer layer. This provides consistent and efficient temperature regulation during the entire reaction process.

4: What type of stirring system does the Jacketed Glass Reactor use?

The Jacketed Glass Reactor uses a motor-driven stirring system supported by ceramic bearings and mechanical seals. This ensures long-term stability, reduced wear, and consistent mixing performance.

5: Can the Jacketed Glass Reactor handle corrosive substances?

Yes, the combination of borosilicate glass and PTFE sealing offers excellent resistance to corrosive chemicals. This allows safe use with a wide variety of solvents and reagents.

6: How does temperature regulation work in this Jacketed Glass Reactor?

Temperature control is achieved by circulating heating or cooling fluids through the jacket surrounding the reactor vessel. This allows for consistent and even heating or cooling during reactions, which is essential for sensitive chemical processes. The system helps prevent overheating or undercooling, improving reaction reliability.

7: Is cleaning the Jacketed Glass Reactor simple?

The smooth borosilicate glass surface makes cleaning easy and prevents chemical residues from sticking. Its corrosion resistance means fewer worries about damage during maintenance. Regular cleaning helps maintain optimal performance and safety.

8: How safe is the Jacketed Glass Reactor for daily use?

Constructed from tempered borosilicate glass, the reactor is resistant to breakage and thermal shock, ensuring safety during operation. The transparent design allows continuous visual monitoring, helping detect any issues early. Overall, it is designed to offer both reliability and user safety.

9: Can the Jacketed Glass Reactor handle aggressive chemicals safely?

Yes, the borosilicate glass is highly resistant to most acids, bases, and solvents, making it suitable for handling aggressive chemicals. This chemical resistance helps prevent contamination and maintains the purity of your reactions. It ensures safe use with a wide range of substances.