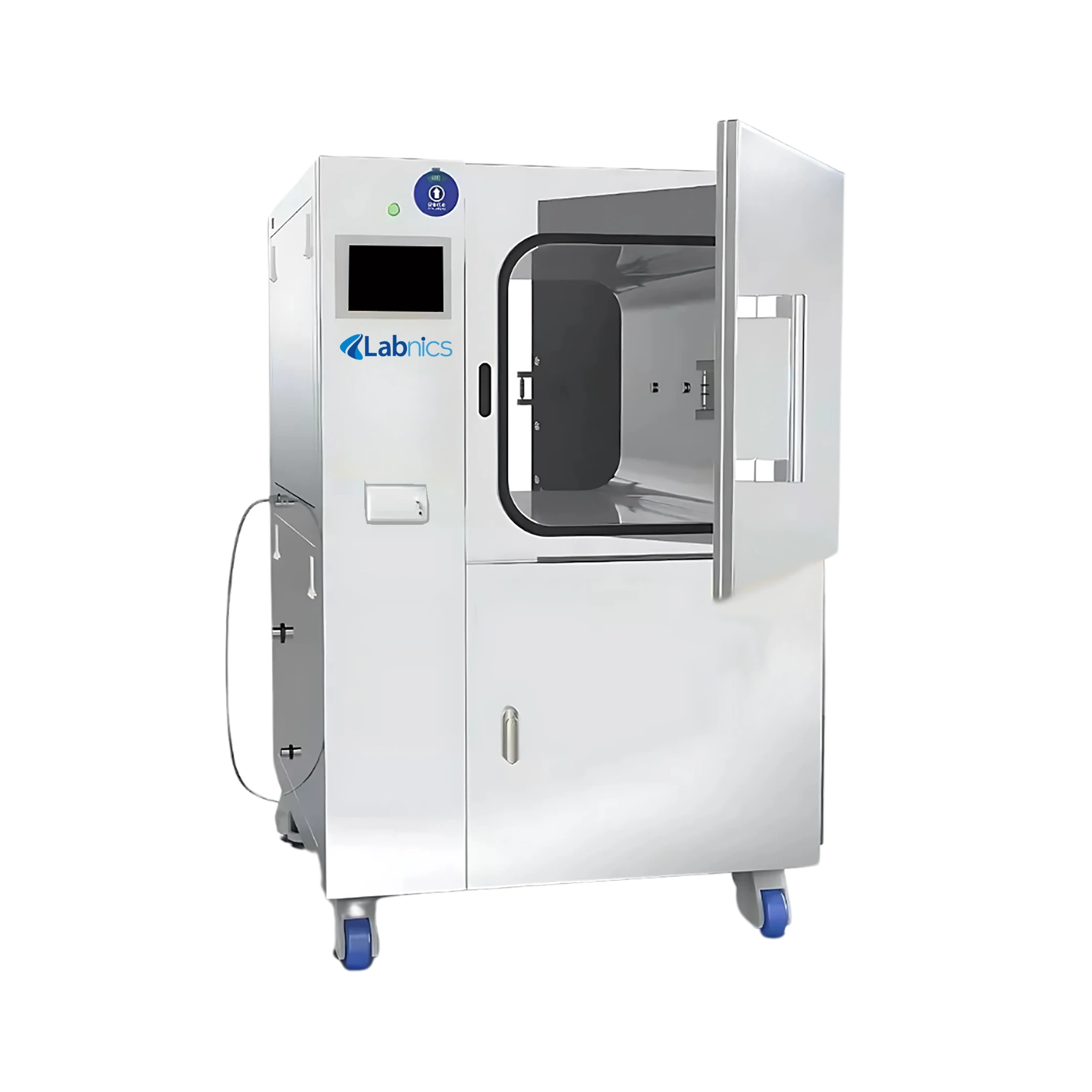

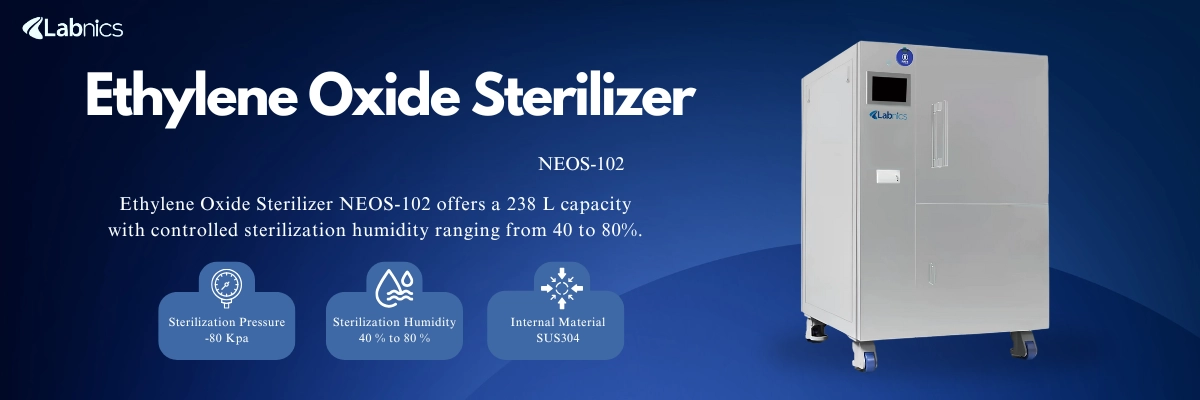

FAQ for Ethylene Oxide Sterilizer NEOS-102

1: What safety features prevent gas leakage during sterilization?

The sterilizer maintains a negative pressure environment throughout the cycle. If leakage occurs, the system automatically triggers cleaning and residual gas removal and alerts users with audible and visual alarms.

2: What happens if there is a power failure during sterilization in the Ethylene Oxide Sterilizer

Our sterilizer’s unique memory function records the sterilization progress and automatically resumes the remaining program after power is restored, ensuring uninterrupted operation.

3: How does the Ethylene Oxide Sterilizer NEOS-102 handle sterilization data storage and printing?

The sterilizer features a thermal printer that provides real-time printing of sterilization data. All records are permanently stored on a USB disk, allowing easy access and long-term documentation for quality control and compliance purposes.

4: What should I do if the Ethylene Oxide Sterilizer does not start?

Check that the power supply is connected properly, ensure the chamber door is fully closed and locked, and verify that all preset conditions such as vacuum and humidity are met. Also, inspect the fuse or circuit breaker if necessary.

5: What is the function of the water detoxifier in the Ethylene Oxide Sterilizer NEOS-102?

The water detoxifier converts residual ethylene oxide gas into harmless components before discharging it through the floor drain, ensuring safe and environmentally friendly exhaust.

6: How does the Ethylene Oxide Sterilizer ensure door safety and ease of use?

he Ethylene Oxide Sterilizer uses a pneumatic door locking system that automatically locks the door during sterilization and unlocks only after the cycle finishes. This automatic operation prevents accidental door openings, enhances user safety, and saves operator effort by eliminating manual handling.

7: What safety measures prevent ethylene oxide gas leakage during sterilization?

Our sterilizer maintains a negative pressure environment inside the chamber to prevent gas from escaping. If any leakage occurs, the system automatically initiates a cleaning phase to remove residual gas and simultaneously triggers audible and visual alarms to alert operators to the issue, ensuring both user safety and environmental protection.

8: What materials and components contribute to the durability and safety of the Ethylene Oxide Sterilizer?

The sterilizer is constructed with corrosion-resistant stainless steel for both the chamber and exterior. It uses durable sealing rings and valves designed for long life and safety. The vacuum pump is engineered to avoid sparks or static electricity, further enhancing operational safety.

9: How is sterilization data recorded in the Ethylene Oxide Sterilizer?

The sterilizer offers real-time printing of cycle data via an integrated thermal printer, allowing immediate access to operation records. Additionally, all sterilization data is securely stored on a USB device, providing a permanent and easily retrievable archive for future reference and documentation.