FAQ for Electronic Analytical Balance NEAB-200

1: Why does the Electronic Analytical Balance use a rear-type electromagnetic force sensor?

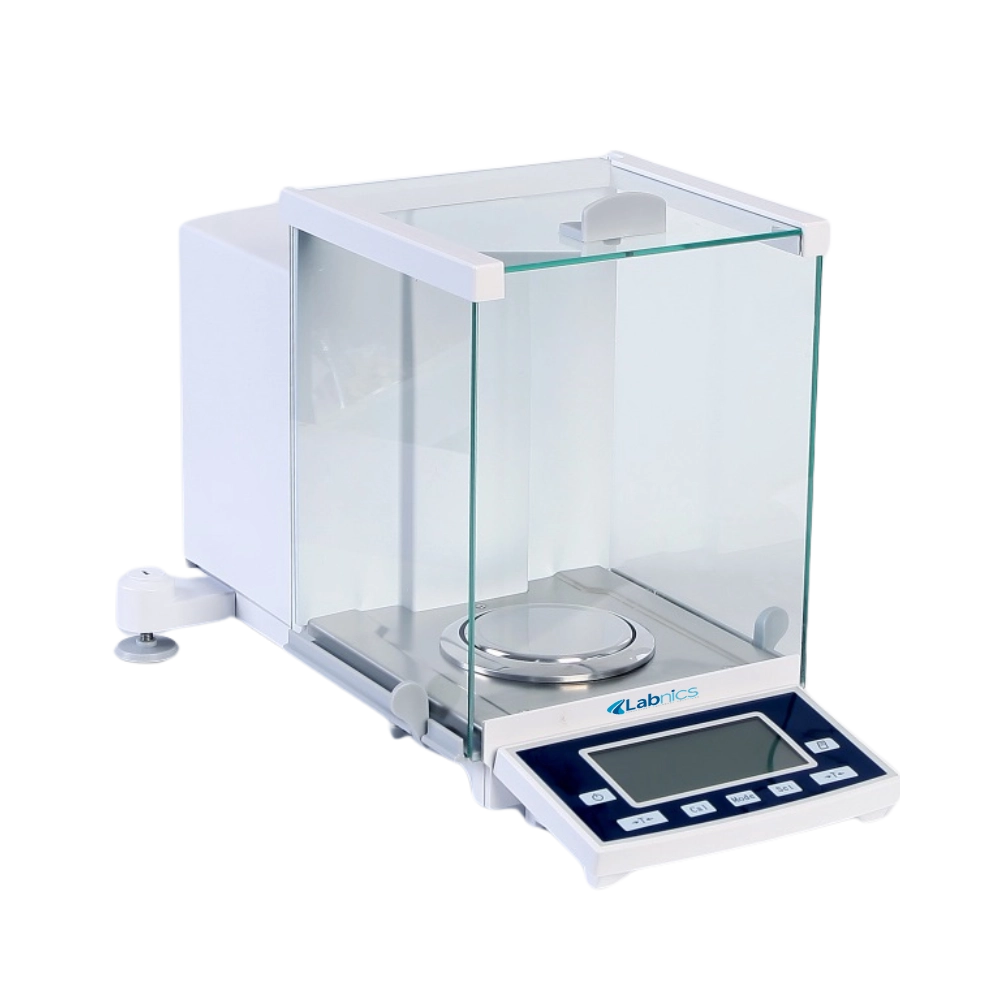

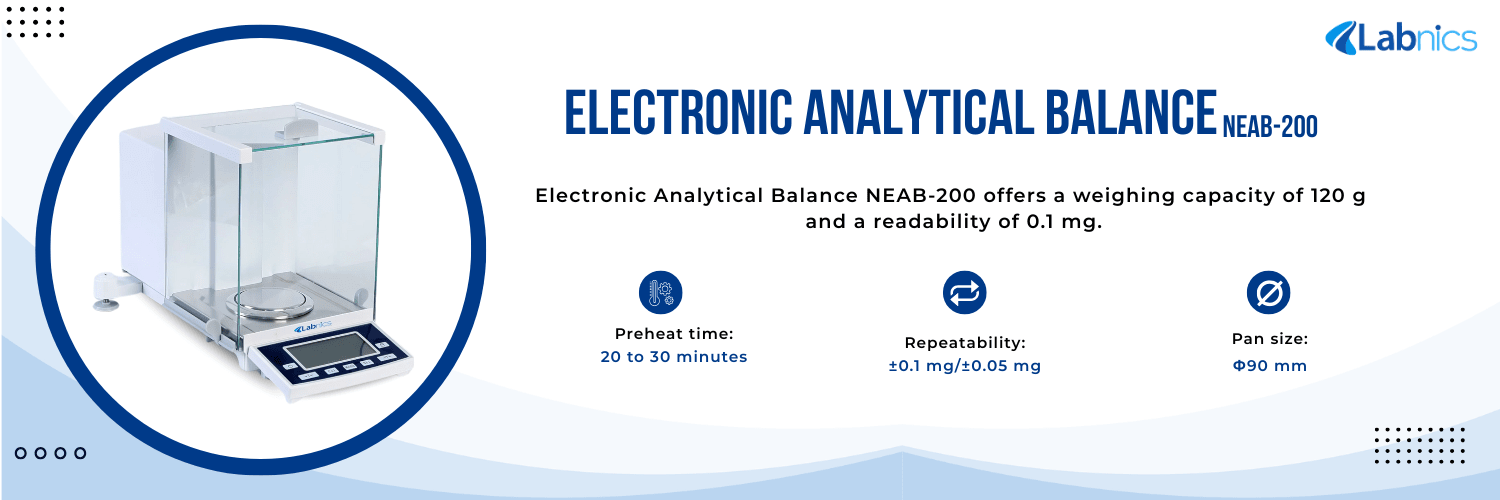

The Electronic Analytical Balance NEAB-200 is equipped with a rear-type electromagnetic force sensor to ensure high sensitivity and stability.

2: What makes the 0.1 mg readability important in analytical weighing?

A readability of 0.1 mg enables the balance NEAB-200 to detect minute changes in weight, making it ideal for precise formulations, chemical analyses, and pharmaceutical work where accuracy is critical.

3: What should I do if the balance displays fluctuating readings?

The Electronic Analytical Balance should be placed on a vibration-free, level surface away from air drafts. Ensure the balance has completed its 20 to 30 min preheat cycle before weighing.

4: How long does the Electronic Analytical Balance take to stabilize a reading?

The Electronic Analytical Balance provides results in as little as 2.5 seconds, depending on sample weight and stability conditions, with maximum response time not exceeding 15 seconds.

5: How can I extend the lifespan of the electronic analytical balance?

To ensure the long-term performance of the NEAB-200, clean it regularly, avoid overloading, calibrate it frequently, and store it in a clean, dry, and vibration-free environment when not in use.

6: Can the Electronic Analytical Balance be used in different industries?

The Electronic Analytical Balance is suitable for a wide range of sectors including scientific research, education, pharmaceuticals, metallurgy, agriculture, and quality control.